High-Quality Cold Rolled Stainless Steel Sheets: Key Updates and Insights

By:Admin

Introduction:

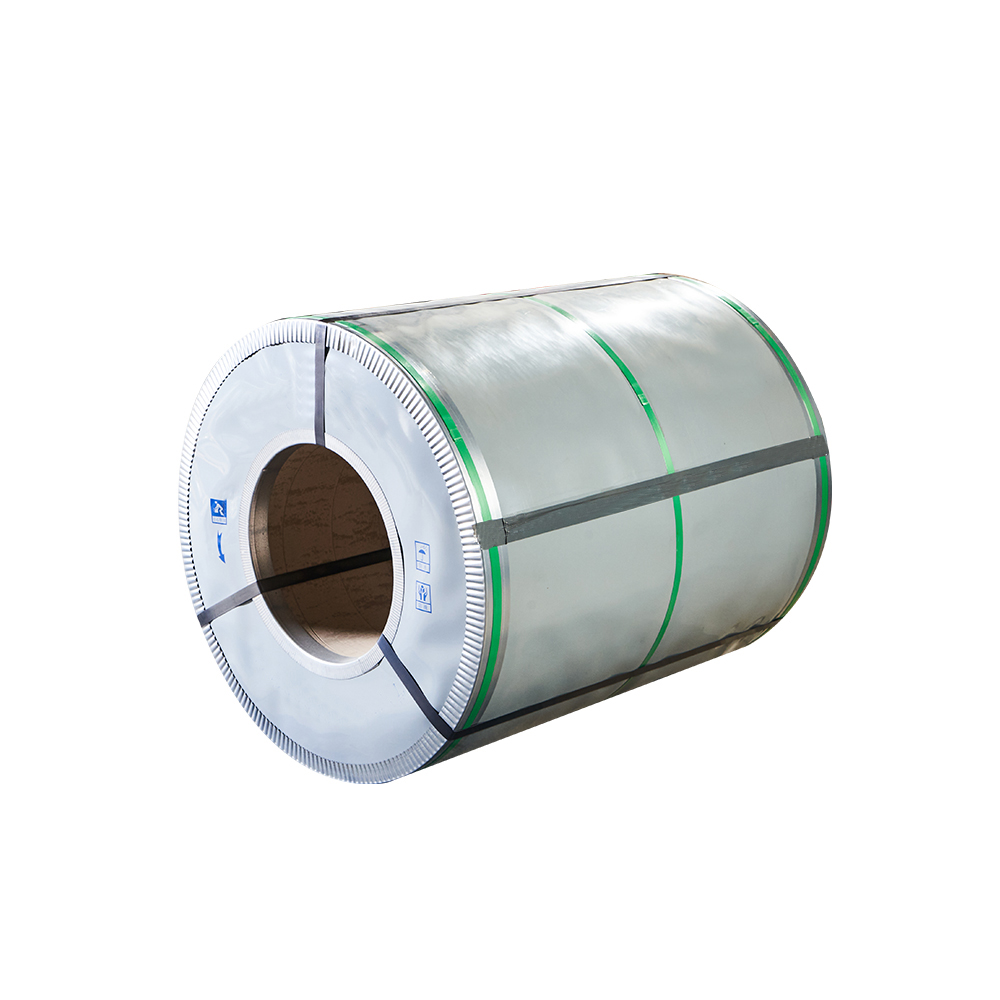

In a remarkable display of ingenuity and commitment to excellence, a leading stainless steel manufacturer has introduced an extraordinary product to their extensive lineup. Providing durability, versatility, and superior performance, the newly launched cold rolled stainless steel sheet has the potential to revolutionize a multitude of industries.

Company Background:

With a rich history spanning several decades, [Company Name] has emerged as a vanguard in the stainless steel manufacturing industry. Driven by a relentless pursuit of quality and innovation, the company has cemented its position as a trusted name in the market by consistently delivering products that exceed customer expectations.

Product Overview:

The recently unveiled cold rolled stainless steel sheet is a testament to [Company Name]'s unwavering commitment to providing cutting-edge solutions. Manufactured using state-of-the-art technology and high-grade materials, this product showcases a seamless blend of strength, durability, and aesthetic appeal.

Key Features and Advantages:

1. Exceptional Strength and Durability: The cold rolling process enhances the structural integrity of the stainless steel sheet, ensuring unparalleled strength and durability. This makes it suitable for various applications that demand resistance to corrosion, high temperatures, and mechanical stress.

2. Versatility: The cold rolled stainless steel sheet boasts exceptional versatility, making it ideal for a wide range of sectors including automotive, construction, food processing, and marine industries. Its ability to withstand extreme conditions and maintain its structural integrity even under duress sets it apart from conventional materials.

3. Aesthetic Appeal: Aesthetics play a crucial role in many industries, and this product surpasses expectations in this regard. With a flawless finish, the cold rolled stainless steel sheet adds a touch of sophistication to any application, making it an appealing choice for architectural projects, interior design, and premium consumer goods.

4. Enhanced Corrosion Resistance: By employing advanced technology, [Company Name] has significantly enhanced the sheet's resistance to corrosion, ensuring an extended service life even in harsh environments. This feature not only reduces maintenance costs but also contributes to sustainable practices, making it an excellent choice for eco-conscious customers.

5. Sustainable Manufacturing: [Company Name] places immense importance on environmental sustainability. The cold rolled stainless steel sheet is a testament to the company's dedication towards reducing its carbon footprint. The manufacturing process employs the most efficient and eco-friendly methods, minimizing waste generation and energy consumption.

Market Impact:

The introduction of the cold rolled stainless steel sheet is expected to have far-reaching implications for various industries worldwide. Its exceptional properties make it a standout choice for manufacturers and consumers alike, providing endless possibilities for innovative applications.

Automotive manufacturers can benefit from its superior strength and resistance to corrosion, ensuring safety and longevity for critical components. In the construction industry, the cold rolled stainless steel sheet can be used in architectural designs, cladding, and structural applications due to its impressive durability and aesthetic appeal.

Additionally, the food processing industry can rely on this product's hygienic nature, corrosion resistance, and ease of cleaning, thereby adhering to strict quality and safety standards. Moreover, marinas, shipbuilders, and offshore industries will value its reliability in harsh marine environments.

Conclusion:

The pioneering cold rolled stainless steel sheet introduced by [Company Name] promises to revolutionize numerous industries with its remarkable attributes. Combining strength, durability, versatility, and aesthetic appeal, this product caters to the ever-evolving demands of modern applications. As [Company Name] continues to push the boundaries of innovation, it reinforces its position as an industry leader, setting new benchmarks for excellence in stainless steel manufacturing.

Company News & Blog

Discover the Benefits of Flex Pipe Exhaust for Your Vehicle

Flex Pipe Exhaust: The Ultimate Solution for Better Engine PerformanceFlex Pipe Exhaust is a revolutionary product that is changing the way we think about vehicle exhaust systems. This innovative technology is designed to improve engine performance, increase fuel efficiency and reduce emissions, all while providing a smooth, quiet ride. It has quickly become a popular choice among automotive enthusiasts and professionals alike, and for good reason.So, what exactly is Flex Pipe Exhaust? At its core, it is a flexible tubing that is designed to connect the engine to the exhaust system. Unlike traditional exhaust systems, which are rigid and inflexible, Flex Pipe Exhaust is able to expand and contract as the engine heats up and cools down. This allows for a smoother, more stable performance, as well as improved fuel economy and reduced emissions.One of the key benefits of Flex Pipe Exhaust is its ability to reduce backpressure in the engine. Backpressure is the resistance that exhaust gases encounter as they leave the engine and move through the exhaust system. This resistance can cause the engine to work harder, which can lead to reduced performance and fuel efficiency. Flex Pipe Exhaust helps to reduce this backpressure, allowing the engine to work more efficiently and deliver better performance.In addition to its performance benefits, Flex Pipe Exhaust is also known for its durability and longevity. Made from high-quality materials, it is designed to withstand harsh conditions and heavy use. This makes it an ideal choice for those who use their vehicles for work, play, or both. Its strength and resilience also help to reduce the risk of damage to other parts of the vehicle, which can save drivers money on repairs over time.At the same time, Flex Pipe Exhaust is also designed with safety in mind. It is manufactured to strict standards and is subject to rigorous testing to ensure that it meets all safety requirements. This means that drivers can trust that their vehicle is equipped with a safe and reliable exhaust system that will help them get to their destination safely.Flex Pipe Exhaust is also easy to install and maintain. Unlike some other exhaust systems, it doesn’t require any complex tools or specialized equipment. In fact, many drivers are able to install it themselves with minimal hassle. Once installed, it requires little maintenance to keep it in good working condition. This makes it an ideal choice for those who are looking for a low-maintenance and user-friendly exhaust system.Despite all of its benefits, Flex Pipe Exhaust is also affordable. It is priced competitively with other high-quality exhaust systems, making it accessible to a wide range of drivers. Whether you are a professional mechanic, a weekend warrior, or simply someone who wants to get the most out of their vehicle, Flex Pipe Exhaust is an investment that is sure to pay off in the long run.As a leading manufacturer of Flex Pipe Exhaust, we are proud to offer a range of products that are designed to meet the needs of drivers everywhere. Our experienced team of engineers and designers have worked tirelessly to develop a product that is both effective and easy to use. Whether you are looking for a replacement for your current exhaust system or an upgrade that will help you get the most out of your engine, we have the product for you.In conclusion, Flex Pipe Exhaust is a game-changing technology that is making a big impact on the automotive industry. It offers a range of benefits that make it an ideal choice for drivers who are looking for better engine performance, improved fuel efficiency, reduced emissions, and a smoother, quieter ride. Whether you are a professional mechanic or simply someone who loves their car, Flex Pipe Exhaust is a product that is sure to deliver results. So why wait? Try it out for yourself today and experience the power of Flex Pipe Exhaust for yourself!

Flexible Auto Exhaust System Products to Meet Your Needs

Auto Exhaust System Flexible Products Unveils Innovative Exhaust SolutionsAuto Exhaust System Flexible Products, a leading manufacturer of automotive exhaust systems, has recently released innovative and state-of-the-art exhaust solutions for cars of all makes and models. The company has been in the business for several years and prides itself on delivering high-quality and cost-effective exhaust systems to its customers.Founded in 2005, Auto Exhaust System Flexible Products has been catering to the automotive industry's needs through its dedication and commitment to providing superior products, customer service, and technical support. The company has a team of experienced engineers and technicians who use the latest technologies and equipment to design and develop exhaust systems for cars.The innovative exhaust solutions from Auto Exhaust System Flexible Products come with advanced features that enhance performance, reduce emissions, and improve fuel economy. The company's product line includes mufflers, catalytic converters, exhaust pipes, and other exhaust components that are made from high-grade materials for durability, longevity, and superior performance.One of the company's flagship products is its flexible exhaust product line. Designed and manufactured in-house, these flexible exhaust systems are highly durable, corrosion-resistant, and provide excellent flexibility, which makes them the ideal solution for demanding automotive applications. Auto Exhaust System Flexible Products' flexible exhaust solutions are ideal for use in cars, trucks, buses, and other vehicles with complex exhaust systems.The flexible products from Auto Exhaust System Flexible Products feature a unique design that allows them to expand, contract and bend, which makes them easy to install and remove. The flexible exhaust solutions also have superior sound-absorbing properties, which means they produce less noise compared to traditional exhaust systems.Auto Exhaust System Flexible Products' flexible exhaust solutions have several benefits over traditional exhaust systems. Firstly, they prevent leaks and noise caused by vibrations that typically occur in engines. Secondly, they are built to withstand extreme temperatures and harsh environments, which improves the longevity of the exhaust system.The flexible exhaust systems are also more cost-effective than traditional systems because they require little to no maintenance, which reduces the frequency of replacements. Furthermore, their lightweight design means they are easy to replace, which reduces the labor costs and downtime associated with traditional systems' replacements.Auto Exhaust System Flexible Products has a reputation for delivering high-quality automotive exhaust products and solutions that exceed customer's expectations. The company's flexible exhaust solutions are fully customizable, and customers can order products based on their specific needs and requirements.In conclusion, Auto Exhaust System Flexible Products continues to be an innovative leader in the automotive exhaust system industry with its latest product line. Its commitment to providing high-quality, cost-effective exhaust solutions has earned the trust and respect of its customers. With the release of its new flexible exhaust product line, Auto Exhaust System Flexible Products is poised to revolutionize the exhaust system industry and provide innovative solutions that meet the needs of modern automotive applications.

Maximizing Safety and Durability: Discover the Versatility of Interlocking Hoses

Interlock Hose Launches Revolutionary New Product for the Industrial MarketInterlock Hose is proud to announce the launch of its latest innovation – a revolutionary new product that is set to change the industrial hose market forever. Drawing on years of experience and expertise, our team of engineers and designers have created a hose that is truly state-of-the-art, delivering unparalleled strength, durability, and performance.One of the key features of our new product is its interlocking design, which enables it to withstand extreme pressures and bending forces without ever losing its shape or integrity. This makes it ideal for use in a wide range of industrial applications, from high-temperature and high-pressure environments to those that involve corrosive chemicals or abrasive materials.But what sets our new hose apart from other products on the market is not just its interlocking design but also the materials and construction methods that we have used to create it. We use only the highest quality raw materials, sourced from trusted suppliers around the world, and subject them to rigorous testing and quality control procedures to ensure that each hose meets our exacting standards.Our hoses are designed to be easy to install and maintain, with a range of fittings and adapters that can be customized to suit the specific needs of each application. They are also built to last, with a long lifespan that can help to reduce maintenance costs and minimize downtime for companies that rely on them.At Interlock Hose, we are committed to providing our customers with the best possible products and services, and our new hose is no exception. We will work closely with each client to ensure that they receive the right hose for their needs, and we offer expert advice and support on everything from installation and maintenance to troubleshooting and repair.With the launch of our new product, we believe that we are setting a new standard for the industrial hose market. Our interlocking hose is stronger, more durable, and more versatile than anything else out there, and we are confident that it will be a game-changer for companies that need reliable, high-performance hoses to keep their operations running smoothly.But don't just take our word for it – try it out for yourself. Contact us today to learn more about our new interlocking hose and how it can benefit your business. We look forward to hearing from you!

Discover the Top Benefits of Stainless Steel Exhaust Flexible Pipe

Stainless Steel Exhaust Flexible Pipe Shines in the Automotive IndustryThe automotive industry is constantly evolving, and with the trend moving towards the use of alternative fuels and the need for increased fuel efficiency, manufacturers are constantly searching for innovative solutions. One such solution is the use of Stainless Steel Exhaust Flexible Pipe to reduce emissions and improve performance.A leading provider of Stainless Steel Exhaust Flexible Pipe, which we will refer to as "SS Pipe" for simplicity, has been making waves in the industry with its high-quality products and innovative approach. SS Pipe specializes in the production of flexible pipes for use in automotive exhaust systems and has gained a reputation for excellence in the industry through its commitment to quality and innovation.SS Pipe's flexible pipes are made from high-quality materials and are designed to withstand the rigors of the automotive environment. The pipes are available in a range of sizes and configurations, making them suitable for use in a wide variety of vehicles, from small passenger cars to large commercial trucks.One of the key benefits of SS Pipe's flexible pipes is their ability to reduce emissions. The pipes are designed to allow for greater flexibility in the exhaust system, which reduces the strain on the engine and improves overall performance. This, in turn, reduces the amount of harmful emissions that are released into the environment.In addition to improving performance and reducing emissions, SS Pipe's flexible pipes also offer a number of other benefits. They are resistant to corrosion and are built to last, making them a great investment for any vehicle owner. They are also easy to install, which means that they can be quickly and easily fitted to any vehicle without the need for specialist tools or expertise.SS Pipe's commitment to quality is evident in every aspect of their products. The pipes are manufactured to strict quality control standards and are rigorously tested to ensure that they meet the highest standards of durability and reliability. This commitment to quality has helped SS Pipe to build a loyal customer base, with customers returning time and again for their high-quality products and excellent customer service.But SS Pipe's commitment to innovation doesn't stop at their product line. The company is also constantly exploring new ways to improve their manufacturing processes and reduce waste. They have invested in state-of-the-art equipment and have implemented best practices to ensure that their manufacturing processes are as efficient and environmentally friendly as possible.In conclusion, SS Pipe's Stainless Steel Exhaust Flexible Pipe is a shining example of innovation in the automotive industry. Their commitment to quality and innovation has helped them to build a loyal customer base, and their flexible pipes have been widely recognized for their ability to reduce emissions and improve performance. With a growing demand for alternative fuel vehicles and the need for increased fuel efficiency, SS Pipe is poised to continue its growth and success in the years to come.

Top-Quality Cold Rolled Strip Stainless Steel - Perfect for Various Applications

Cold Rolled Strip 316L Stainless Steel: The Perfect Solution for Precision Engineering Applications[City], [Date] - Today, we are excited to introduce a revolutionary product that is set to redefine the precision engineering industry. Our company, [Company Name], has recently developed and launched a new line of cold-rolled strip 316L stainless steel. With its exceptional characteristics and innovative manufacturing process, this product is the ultimate solution for a wide range of applications in various sectors.Traditionally, precision engineering requires materials that possess outstanding durability, corrosion resistance, and excellent mechanical properties. Recognizing these needs, our team of dedicated experts has meticulously engineered cold-rolled strip 316L stainless steel to meet and exceed these demands. By combining precision with quality, our product provides unparalleled performance and reliability.One of the standout features of our cold-rolled strip 316L stainless steel is its exceptional corrosion resistance. This makes it particularly suitable for applications that are exposed to harsh environments or corrosive substances. The addition of molybdenum to the steel composition enhances its resistance against pitting and crevice corrosion, further extending its longevity and ensuring consistent performance over time.Furthermore, the cold-rolled process that our stainless steel undergoes guarantees exceptional dimensional accuracy and surface quality. This makes our product the go-to choice for applications that require tight tolerances and smooth surfaces, such as electronic components, medical devices, and automotive parts. The uniform thickness and smooth finish of our stainless steel strip enable precision machining and maximize productivity for manufacturers.Another advantage of cold-rolled strip 316L stainless steel is its superior mechanical properties. The material exhibits high tensile strength, enabling it to withstand heavy loads and stresses without compromising its overall integrity. Its excellent ductility allows for easy forming and shaping, making it versatile for a wide range of design requirements. These properties make our stainless steel strip ideal for components used in aerospace, defense, and industrial sectors.It is worth highlighting that our company has demonstrated a commitment to sustainable manufacturing practices. We ensure that our cold-rolled strip 316L stainless steel is produced using eco-friendly processes that minimize environmental impact without compromising the product's integrity. By adopting these responsible practices, we contribute to a greener future while providing our customers with the highest quality stainless steel strip.In addition to our top-of-the-line product, [Company Name] prides itself on exceptional customer service. Our dedicated team of experts is well-equipped to provide technical support and guidance based on individual customer needs. We prioritize collaborating with our clients to understand their specific application requirements and provide tailored solutions to meet their unique challenges. With [Company Name], customers can expect a seamless experience from inquiry to delivery.In conclusion, the introduction of cold-rolled strip 316L stainless steel by [Company Name] marks a significant milestone in the precision engineering industry. With its exceptional corrosion resistance, superior mechanical properties, and eco-friendly manufacturing practices, our stainless steel strip is set to revolutionize a wide range of applications. We are excited to provide our customers with a game-changing solution that combines precision, quality, and sustainability. Contact us today to experience the unparalleled performance of our cold-rolled strip 316L stainless steel.

High-Quality 304l Stainless Steel Coil: A Durable and Versatile Choice

article.304L Stainless Steel Coil Gains Popularity in Various IndustriesStainless steel is a popular choice for various industries, thanks to the material’s durability, corrosion resistance, and versatility. Stainless steel coils, in particular, are widely used in the manufacturing of appliances, automotive parts, aerospace components, kitchenware, and construction materials, among others.One of the most sought-after stainless steel coils in the market today is the 304L Stainless Steel Coil. Produced by a leading stainless steel manufacturer, this coil has become a reliable and top-performing option for businesses in different industries.What is 304L Stainless Steel?Before we delve deeper into the advantages of this stainless steel coil, let us first understand what 304L Stainless Steel is. This type of stainless steel contains low carbon, making it ideal for high-temperature applications. The “L” in the name stands for “low carbon,” which prevents intergranular corrosion during welding operations.304L Stainless Steel is an austenitic steel, which means that even when exposed to heat, it remains non-magnetic. It also boasts excellent corrosion resistance, making it suitable for use in harsh environments where corrosive materials may come into contact with the metal.Applications of 304L Stainless Steel CoilDifferent industries rely on 304L Stainless Steel Coil for different purposes. Here are some examples:1. Chemical Processing - The chemical processing industry generates a vast array of chemicals, acids, and salts that can damage equipment. 304L Stainless Steel Coil's corrosion resistance and low carbon content make it ideal for storing and transporting these chemicals.2. Food and Beverage Industry - Stainless steel is a popular material in the food and beverage industry due to its hygienic and easy-to-clean nature. 304L Stainless Steel Coil is a top choice for constructing equipment and tools used in the production and processing of food and beverages.3. Construction Industry - Many construction projects require materials that can withstand harsh conditions, including extreme temperature changes, moisture, and harsh chemicals. 304L Stainless Steel Coil's durability and corrosion resistance make it an ideal option for roofing, cladding, and structural steel components.4. Automotive Industry - Stainless steel coils are widely used in the automotive industry for their resistance to corrosion, strength, and durability. 304L Stainless Steel Coil is a reliable choice for manufacturing automotive parts and components, including exhaust systems, suspension components, and fuel tanks.Advantages of 304L Stainless Steel Coil304L Stainless Steel Coil has several advantages that make it a top choice for various industries:1. Corrosion Resistance - The alloy composition of 304L Stainless Steel makes it highly resistant to corrosion, even in harsh environments.2. Durability - 304L Stainless Steel Coil is durable and can withstand high temperatures, making it suitable for use in applications that require resilience.3. Low Maintenance - Stainless steel requires minimal maintenance compared to other materials, lowering the total cost of ownership.4. Hygiene - Stainless steel is an excellent choice for applications involving food and beverages due to its hygienic and easy-to-clean nature.Why Choose {} for 304L Stainless Steel CoilThe popularity of 304L Stainless Steel Coil is due in part to the reputation of the manufacturer. {} is a trusted supplier of high-quality stainless steel products with over a decade of experience in the industry.{}'s 304L Stainless Steel Coil is produced using state-of-the-art technology, ensuring the highest quality and consistency. The company offers a range of customization options to meet the unique needs of each client, including thickness, width, and surface finishes.In Conclusion304L Stainless Steel Coil is a top option for different industries due to its durability, strength, and corrosion resistance. {} is a reliable supplier of this product, offering high-quality and customizable options to meet the unique needs of their clients. With the advantages and reliability of 304L Stainless Steel Coil, businesses can expect long-lasting and efficient performance from their equipment and components.

All You Need to Know About 1.4841 Stainless Steel Sheet: Properties, Applications, and more!

Title: Unveiling 1.4841 Stainless Steel Sheet: A High-Quality Product for Diverse ApplicationsIntroduction:In the ever-growing world of industrial materials, stainless steel remains one of the most versatile and sought-after choices for its durability and corrosion-resistant properties. Today, we present the exceptionally reliable and high-quality 1.4841 Stainless Steel Sheet. Manufactured by a renowned company, this product stands out in the market due to its exceptional characteristics, making it an ideal solution for various industries worldwide.1. Resistant to Corrosion:The 1.4841 Stainless Steel Sheet is highly regarded for its exceptional resistance to oxidation and corrosion. Its superior composition includes elements such as chromium, nickel, and silicon, which enhance its ability to withstand extreme environments, including high temperatures and exposure to chemicals. This attribute ensures its longevity and high performance even under the harshest conditions.2. Thermal Stability:Due to its excellent resistance to oxidation and scaling at elevated temperatures, the 1.4841 Stainless Steel Sheet finds extensive use in applications requiring exceptional thermal stability. This makes it an ideal choice for industries such as petrochemicals, power generation, heat treatment, and furnace components.3. Structural Integrity:The 1.4841 Stainless Steel Sheet boasts remarkable structural integrity, making it resistant to creep deformation even at elevated temperatures. This property is particularly valuable in applications where the material is subjected to continuous stress, such as in power plants, heat exchangers, and combustion chambers. Its structural stability ensures longevity and reliability under demanding conditions.4. Versatility:The versatility of the 1.4841 Stainless Steel Sheet allows for a wide range of applications across various industries. From manufacturing components for chemical processing plants to use in the automotive and aerospace industries, this product exhibits excellent compatibility and adaptability. Its robustness, combined with its corrosion resistance, ensures optimal performance in diverse environments.5. Manufacturing Excellence:The manufacturer of the 1.4841 Stainless Steel Sheet takes pride in its state-of-the-art production facilities and rigorous quality control procedures. With a commitment to meeting international standards, their stringent testing and inspection processes ensure that each sheet is flawless and meets the highest industry specifications.Conclusion:The 1.4841 Stainless Steel Sheet represents a top-tier product in the stainless steel market, renowned for its exceptional resistance to corrosion, thermal stability, structural integrity, and versatility. It serves as a reliable solution for numerous industries seeking a high-performance material that can withstand challenging environments. The manufacturer's commitment to excellence and quality ensures that customers receive a product that not only meets their expectations but exceeds them. The 1.4841 Stainless Steel Sheet is poised to become a staple choice for engineers, fabricators, and industries worldwide, offering reliable and durable solutions to their diverse needs.

Guide to Choosing the Right Type of Stainless Steel for Your Needs

Stainless steel is a highly versatile and durable material that has become increasingly popular in recent years. Its unique properties have made it a go-to choice for many industries, from construction and architecture to medical and food processing. Among the many different types of stainless steel available, 316 and 316L are some of the most widely used.Recently, one of the leading firms in the manufacturing of 316 and 316L stainless steel revealed some interesting insights into the products. This manufacturer is renowned for producing high-quality stainless steel products that meet the most demanding industry requirements, including high-temperature resistance, corrosion resistance, and durability.One of the key features of 316 stainless steel is its excellent corrosion resistance, which is due to the addition of molybdenum. Molybdenum increases the metal's pitting and crevice corrosion resistance in chlorides, making it ideal for marine applications as well as environments where corrosive chemicals are present. It also has high strength and toughness, making it ideal for use in harsh environments where temperature fluctuations and mechanical stresses can cause metal fatigue.On the other hand, the 316L variant is a low carbon modification of 316 that is highly resistant to sensitization. This means that it is less prone to corrosion in the heat-affected zones of welded joints, making it ideal for use in applications where welding is required. Additionally, this material has excellent resistance to pitting and crevice corrosion, making it an excellent choice for applications such as architectural structures and food processing equipment.The manufacturer specializes in the production of high-quality 316 and 316L stainless steel products, ranging from pipes, tubes, and fittings to sheets, plates, and bar products. The company uses advanced manufacturing processes to ensure that each product meets the exact specifications of the customers.One of the notable things about this manufacturer is their strict adherence to industry standards and certifications. This includes ISO 9001:2008, PED 97/23/EC, and AD2000 Merkblatt WO. The company also has rigorous quality control measures in place to ensure that every product meets the highest standards of quality and durability.The manufacturer is proud of its commitment to sustainability, which they achieve through responsible sourcing of raw materials, energy-efficient production processes, and responsible use of resources. Additionally, the company supports local communities by providing employment opportunities and investing in community initiatives.Customers around the world who have worked with this manufacturer have praised the company's dedication to quality, reliability, and customer satisfaction. The manufacturer also provides exceptional customer support, from initial consultations to after-sales service.Overall, 316 and 316L stainless steel are versatile materials that offer excellent corrosion resistance, durability, and strength. When combined with the manufacturing expertise of this leading firm, the result is top-quality stainless steel products that meet the most demanding industry requirements. Whether you are looking for pipes, tubes, fittings, sheets, plates, or bar products, this manufacturer's stainless steel products are sure to surpass your expectations.

Exploring the Potential of Stainless Steel Raw Materials: An In-depth Analysis

Stainless Steel Raw Materials Aims to Revolutionize the Steel IndustryStainless Steel Raw Materials (SSRM) is a U.S.-based company that has set its sights on revolutionizing the steel industry. With a primary focus on the production and supply of premium-quality stainless steel, the company has positioned itself as a major player in the market.The company has a long history of producing high-quality steel products. Stainless Steel Raw Materials prides itself on the use of advanced techniques and equipment to manufacture top-quality raw materials that meet the exacting standards of the modern economy. They are committed to meeting the needs of their clients by providing a wide range of stainless steel products that meet their specific requirements.One of the key factors behind the success of Stainless Steel Raw Materials is its focus on quality control. The company understands the importance of ensuring that every product that leaves their factory meets the highest standards of quality. As such, they engage in rigorous testing and inspection processes to ensure that they deliver only the best.The company invests heavily in research and development to remain at the forefront of the industry. Their R&D team is dedicated to developing new and innovative techniques and technologies that will help them to produce the highest quality raw materials more efficiently. By doing so, they are able to reduce their costs, which allows them to offer their products at competitive prices. This, in turn, has helped them to expand their customer base and grow their business.Stainless Steel Raw Materials currently supplies its products to a wide range of industries. From automotive to construction, the company has created a niche for itself by providing customized steel products for a variety of applications. They have a vast range of product offerings, including stainless steel sheets, tubes, coils, pipes, and fittings.The company is committed to sustainable business practices. They are aware of their carbon footprint and strive to minimize it as much as possible. They do this by optimizing their production processes to reduce waste, recycling materials, and using energy-efficient equipment.As part of their expansion plans, they have recently invested in new equipment and technologies to increase their production capacity. Their goal is to meet the growing demands of their customers while maintaining the highest standards of quality.One of the key factors behind the success of Stainless Steel Raw Materials is its customer-centric approach. They understand that their customers are the lifeblood of their business. They are committed to building strong relationships with their clients and to providing them with the best possible service.In addition to their excellent customer service, the company offers competitive prices for their products. They achieve this by streamlining their operations to minimize costs while maintaining high-quality standards. As such, they have been able to expand their customer base, which has helped them to grow their business.Stainless Steel Raw Materials has a team of experts who are always available to help their clients. They have a deep understanding of the steel industry, and they are always willing to provide guidance and advice to help their clients make informed decisions.To sum up, Stainless Steel Raw Materials is a company that has set its sights on revolutionizing the steel industry. With its focus on quality control, investment in research and development, and commitment to sustainable business practices, the company is well-positioned to meet the growing demands of its customers. Their customer-centric approach, competitive prices, and deep industry expertise make them an excellent choice for anyone in need of high-quality stainless steel products. Regardless of the application, Stainless Steel Raw Materials has the expertise and experience to deliver customized solutions that meet the exacting standards of its customers.